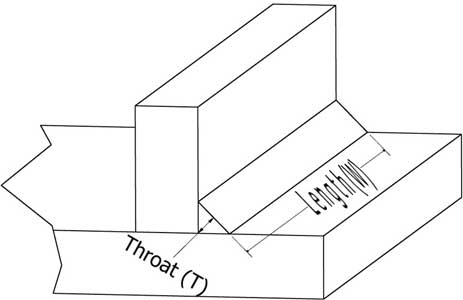

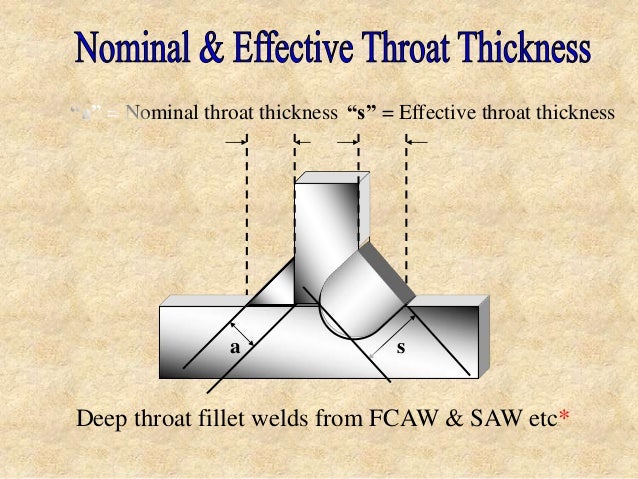

Effective Throat Thickness

Ratio of a Fillet weld Leg to the throat

As shown, the maximum measure throat dimension would be 0.264' based on this calculation. A proper gauge measuring the actual throat dimension should be used to assess if this criteria has been. Where f uw is the weld metal strength, a is the weld throat thickness and L is the weld length. The term 0.6 f uw represents the design shear stress of the weld metal where the value of f uw is the nominal tensile strength of weld metal given in Table 7.3. = Throat area of fillet weld mm 2, in 2 B = Width of weld mm, in s = Web thickness mm, in L = Length of weld mm, in r = Weld radius mm, in t = Flange thickness mm, in H = Height of fillet weld mm, in a = Fillet weld cross sectional area.

Weld Throat Thickness

Effective Throat Thickness Of A Fillet Weld Depends Upon

I am no math whiz so my explanation may be crude. (9th grade last math class).

On a right triangle the hypotenuse forms a 45 degree angle. If you split the center of the face (hypotenuse) and go from there to the root you have another right triangle. If you then take the leg size and multiply it times the COSINE of the Angle which for a 45 degree angle is .707 and multiply that times the leg, you get the throat thickness.

This only works for joints that are at 90 degrees and have flat or convex faces. Here are some facts (unless I am wrong which is possible)

1) an equal leg fillet weld in a 90 degree joint the width of the face is 2 times that of the throat. So if you can only measure the face AND the leg sizes are equal you can approximate the throat.

2) If you can only measure the smallest leg, the throat will be .707 times that dimension.

3) You can only use a throat gage on a flat or concave weld. If a throat dimension is called for and the weld is convex, you must calculate the throat.